DIY Aggregate Paving VS StreetScape Aggregate Paving:

Aggregate pavers are durable, decorative, and an investment for any home or business space. StreetScape offers an extensive variety of stunning and functional aggregate pavers for your aggregate paving. Find out whether you would prefer creating your own aggregate pavers or purchasing aggregate pavers from StreetScape.

Aggregate Paving:

Aggregate paving consists of aggregate pavers which are laid out on a surface in a specific pattern. Aggregate paving is generally made from a mixture of cement, water, and aggregates. Aggregate paving is specifically made with intentionally exposed aggregates.

Aggregates are important in concrete as they provide structure and volume to your concrete. There are various aggregate types available which range from man-made to natural to recycled materials. This is a list of common aggregates used in concrete.

- Sand.

- Stones.

- Gravel.

- Slag.

- Recycled Materials, such as concrete or broken road.

The purpose of exposed aggregates in aggregate pavers is to add a decorative element to your pavers. This is achieved through choosing specific aggregate types, sizes, and colours to add a beautiful yet still functional element to outside your business or home.

Aggregate pavers are versatile in their use. This is a list of the common spaces you will find aggregate paving in either a home or business.

- Sidewalk.

- Steps.

- Driveway.

- Garden courtyard.

- Pathway.

- Outdoor area at home.

- Around a pool.

- Outdoor shower.

Benefits of Aggregate Paving:

Aggregate pavers have many benefits when they are incorporated into your home or business.

Reduced Cracking: Aggregate pavers are a great alternative to solid-pour concrete driveways, sidewalks, or other large areas with high traffic. Solid-pour concrete slabs are prone to cracking when exposed to extreme weight or fluctuations in temperature. Aggregate pavers are smaller which means they can expand and contract individually in temperature fluctuations which reduces the chance of cracking. Aggregate pavers are also suitable to weight and high-traffic with fewer chances of cracking. If an aggregate paver does crack, it is more affordable to replace one versus redoing an entire solid-pour concrete slab.

Less Water Runoff: Large solid surfaces can cause water runoff. This can be destructive and dangerous. Aggregate pavers with gaps in between each paver allow for space for the water to seep into the ground and therefore reduce water runoff issues.

Low Maintenance: Aggregate pavers are lower maintenance than many conventional pavers. Aggregate pavers will also last longer if they are sealed with a finish that will protect the concrete from corroding. There are various aggregate paver finishes available in a variety of colours and gloss levels.

Variety of Sizes: Aggregate pavers come in numerous sizes and shapes. No matter what project you are needing aggregate pavers for, there will be an ideal design suited to the space.

Different Decorative Looks: Often the deciding factor on which aggregate paver to choose is based on the overall look of the chosen aggregate. The wide variety of aggregate types allows for many different decorative looks. Aggregate pavers are suitable for a wider variety of homes and businesses due to the varying styles and colours.

DIY Aggregate Pavers:

Aggregate pavers are a fun DIY project to take on. Creating your own aggregate pavers can be a way to ensure the pavers have the exact design you are looking for. You will need these materials to create your aggregate pavers.

- Paver mould.

- Aggregate.

- Cement.

- Water.

- Wheelbarrow and spade OR concrete mixer.

- Stick.

- Chicken wire.

- Concrete trowel.

- Sheet plastic.

- Sponge.

Follow these ten steps to create your own aggregate paving.

1) Paver Mould:

You will need a paver mould in the desired size and shape you want your aggregate paver to be. Your paver mould should be in a material that is easy to demould the aggregate paver. Silicone paver moulds can be purchased, or they can be created out of repurposed materials, such as a plastic box or scrap wood. Spray your paver mould with a non-stick material so that the paver will come out easily.

2) Line Your Paver Mould with Aggregate:

Arrange your chosen aggregate on the bottom of your paver mould in a single layer. Ensure that the aggregate is tightly packed together to minimise gaps in between the aggregate. Using different sized aggregates will allow you to have a well-graded aggregate.

It is important to ensure that your aggregate is clean of any chemicals or clay before you place them in the mould as these can affect your concrete.

3) Mix Cement with Water:

Mix cement with water in the correct ratio to create your concrete. You can mix the concrete mixture with a spade in a wheelbarrow. For larger projects, we suggest purchasing or hiring a concrete mixer to create perfectly mixed concrete. Your concrete mixture should be similar in consistency to a cake batter.

4) Pour Wet Concrete:

Generally, the minimum thickness an aggregate paver should be is 40mm. Choose your desired aggregate paver thickness and pour the concrete mixture to half of this thickness in your paver mould. Ensure the aggregate layer is fully covered. Tap the concrete mixture gently with a stick, without disturbing the aggregate, to remove any air pockets.

5) Insert Chicken Wire into Concrete Mixture:

Cut a piece of chicken wire to slightly smaller than the size of your paver mould. Lay your sheet of chicken wire on top of your concrete mixture in your paver mould. The chicken wire provides the concrete with something structural to bind to which will increase the strength of your aggregate paver.

6) Pour Remaining Concrete Mixture:

Pour the remaining amount of concrete mixture over the chicken wire until you reach the desired thickness of your aggregate paver.

7) Smooth Concrete Surface:

Use a concrete trowel to smooth the surface of your concrete so that the base of your aggregate paver is uniform.

8) Cover Your Paver with Sheet Plastic:

Cover the green concrete paver with a sheet of plastic. This helps reduce the chances of the water evaporating rapidly out of your aggregate paver as this can lead to weaker concrete and cracking. Allow the concrete in your aggregate paver to cure for at least a week.

You can additionally lift the sheet plastic every day and spray a fine mist of water on the aggregate paver. This process is known as wet curing, which prolongs the drying time but increases the strength of your concrete paver.

9) Remove the Aggregate Paver:

Gently remove the aggregate paver from the paver mould.

10) Clean the Aggregate Paver:

Place your aggregate paver right-side-up and clean the exposed aggregates with a sponge and water. This will remove the hazy look from the concrete. Continue this process with clean water until your aggregate paver is clean.

Additionally, you can also use a wire brush if there is excess concrete on your aggregate or if you want to expose your aggregate more.

StreetScape Aggregate Pavers:

StreetScape is a landscaping element manufacturer. From bollards to bins to kerbs to aggregate paving, StreetScape is your one-stop shop for all landscaping needs. All StreetScape landscaping elements are suitable for your home or business.

StreetScape has been in the aggregate paving industry for many decades. This has provided us with the experience to create exposed aggregate pavers of exceptional quality. At StreetScape, you will find aggregate pavers at an affordable price made with natural stones.

StreetScape offers aggregate pavers in brick shape and slab shape, and these can vary in sizes to suit your needs.

StreetScape offers three thicknesses for the aggregate pavers.

- 25mm.

- 50mm.

- 75mm.

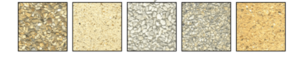

StreetScape offers five variations in aggregate paver colours. StreetScape only uses natural stone so you should expect a slight colour variation in your aggregate pavers. Aggregate paver colours are also limited to the availability of the aggregate.

- Boland.

- Wheatstone.

- Ivory.

- Granite.

- Namib.

The wide range of colour and aggregate sizes in the StreetScape aggregate pavers allows for a wider range of aesthetic designs and suit various spaces in your home or business. It is easy to find an exposed aggregate paver that you fall in love with at StreetScape.

You can purchase StreetScape aggregate paving with a clean cut edge or a bevel edge. The choice is yours and depends on your design style or the purpose of your aggregate paving.

StreetScape uses a dense aggregate mixture to create the aggregate paving. This is important for the aesthetic of the aggregate paving as well as reduces the chances of your aggregate paving chipping, allowing you to enjoy your high-quality StreetScape aggregate paving for longer.

StreetScape puts you first. We finish all our aggregate pavers by hand to ensure that you receive uniform pavers of excellent quality. We hold ourselves to a high standard so that you receive high-quality aggregate pavers every time.

DIY Aggregate Pavers VS StreetScape Aggregate Pavers:

We compare DIY aggregate pavers to StreetScape aggregate pavers to help you decide which option best suits your project and lifestyle.

1) Ease:

DIY aggregate pavers are an exciting project but there are a few catches. The process of creating your aggregate pavers is time-consuming and there is a week waiting period for your aggregate pavers. You will need a fairly large space to allow for your aggregate pavers to cure without being moved or disturbed. Creating your own aggregate pavers requires time and energy which makes them a difficult project for many lifestyles.

Purchasing StreetScape aggregate pavers is instantaneous. StreetScape has taken the time and effort out of your aggregate pavers which allows you to begin enjoying your aggregate pavers sooner.

StreetScape aggregate pavers are also suggested for larger projects. The time, effort, and space required to create numerous aggregate pavers may be unrealistic for your lifestyle and home. StreetScape has the exact aggregate paver amount, sizes, and edging you require for any project scope.

2) Durability:

Ensuring your DIY aggregate pavers are durable is important for their longevity. Mixing the concrete perfectly to ensure strength and durability is difficult. The last thing you want after the effort you have put into your aggregate pavers is for them to crack or chip after minimal wear.

StreetScape aggregate pavers are created to be strong, high-quality, and durable. Using StreetScape aggregate pavers reduces the risk of having to constantly replace your aggregate pavers which will end up costing you more money.

3) Laying Pavers:

It is suggested to use a professional paving contractor to lay your aggregate pavers for both your DIY aggregate pavers and StreetScape aggregate pavers. Laying aggregate pavers is a specific process that requires experience and skill. Hire a contractor who is associated with the Brick Paving Institute of South Africa for quality work.

It is important to remember that there will be an additional cost for the contractor who will lay your pavers. This you will need to work into the overall affordability of your aggregate paving project and decide whether it is worth buying quality StreetScape aggregate pavers or risk DIY aggregate pavers.

Create your own aggregate pavers or purchase high-quality aggregate pavers from StreetScape.